Transformer Monitoring System

DESIGNED BY EXPERTS, BUILT FOR INDUSTRIAL ADAPTION & EFFICIENCY

MOTWANE DIGITAL in collaboration with industry experts have developed the state-of-the-art Transformer Monitoring System that has been satisfactorily adopted by number of industries and they rely on our solution for their monitoring needs.

Why Transformer Monitoring System?

Proactive Maintenance for Reliable Operations

Only 25%

Transformer faults can be detected by offline oil analysis

14000

Major Failures Cost $14,000 Per MVA In Property Damage. According To A Study From 2003

30%

of Transformers That Fail Are Beyond Repair

About Motwane Digital

State-of-the-Art Hardware

Our Hardware is built to stand most hostile conditions. Its universal approach makes it compatible to any kind of transformer and ensures all the data can be fetched.

Get in Touch with our team to Know More

Transformer Monitoring System

Motwane Digital Solutions are committed to delivering robust systems that empowers engineers to efficiently operate and improve productivity while adapting to industry best practices.

Fleet Monitoring

Intutive dashboards designed to deliver only the critical information

Fleet Monitoring

We deliver the best solution and provide a business strategy that makes you a full professional.

Predictive Maintenance

Detect potential issues early to prevent failures and unplanned downtime.

Fleet Monitoring

We deliver the best solution and provide a business strategy that makes you a full professional.

Alerts & Notifications

Get Instant alerts via SMS, E-mails and WhatsApp messages

Fleet Monitoring

We deliver the best solution and provide a business strategy that makes you a full professional.

Improve efficiency

Optimize energy usage and transformer performance for maximum output.

Fleet Monitoring

We deliver the best solution and provide a business strategy that makes you a full professional.

Prolong asset Life

Track Real-time ageing of transformer and plan interventions needed to maximize asset life

Fleet Monitoring

We deliver the best solution and provide a business strategy that makes you a full professional.

Data-Driven Decision Making

Identify root-cause and operational profile for O & M planning.

Fleet Monitoring

We deliver the best solution and provide a business strategy that makes you a full professional.

Digitalized Log Book

Capture all the electrical and temperature parameters on real-time basis. Plus store and access maintenance records effortlessly in a cloud-based system.

Fleet Monitoring

We deliver the best solution and provide a business strategy that makes you a full professional.

Reduce Maintenance Cost

Minimize repairs and extend service life with smart diagnostics.

Fleet Monitoring

We deliver the best solution and provide a business strategy that makes you a full professional.

Discover Our Complete Collection

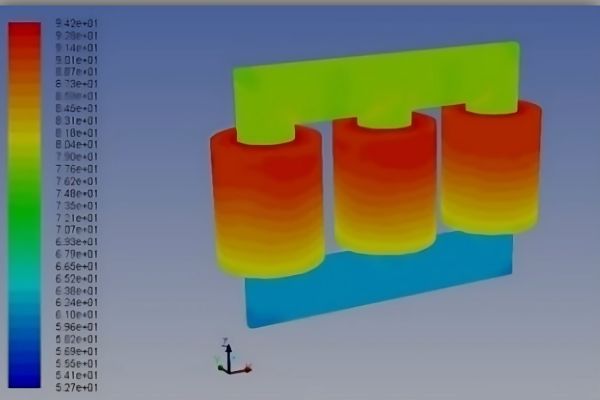

Early Hotspot Detection helped in proactive maintenance

"Hotspot acts as leading indicator of internal problems in the transformer. Learn how MOTWANE DIGITAL helped customer in hotspot activity detection with proprietary AI Algorithm.

OLTC wear and tear damage

Onload tap-changers are susceptible to wear and tear damage. Learn how MOTWANE DIGITAL supported customer with data-driven insights to plan for OLTC Maintenance.

FAQ

Frequently Asked Questions

We have separate solutions for both power transformer and distributive transformer. The commercials will also varying accordingly.

Motwane’s predictive algorithms are highly accurate, thanks to continuous training and improvement based on large datasets. Our AI models evolve with your asset’s behaviour, ensuring reliable predictions and actionable insights over time.

Yes, Motwane’s digital solutions can assist in tracking key metrics and generating reports for regulatory compliance and internal audits. Our platform makes it easier to monitor and document asset performance for compliance purposes.

yes, we can provide you the data backup on your server with AI integration.

The on-boarding processs is as easy as 1-2-3…… Site Survey -> I & C -> Hand-over and Training.